- Main page

- News

EQUIPMENT FOR PURCHASING "CLEAN COAL"

10/5/2021

Our country is very rich in coal reserves and is a world leader in terms of coal production. According to some estimates, coal reserves are expected to reach 500 to 1,000 years, including current consumption levels. Therefore, the fact that today the share of coal energy has reached 85% is surprising.

However, in recent years the world's alternative energy sources are developing rapidly. In civilized countries, solar and wind energy began to compete with coal (about 1% of our country uses alternative energy sources). It is no secret that coal causes a lot of damage to the environment and ecology. In industrial areas, there have even been cases of animals eating grass in the area when the waste from coal mining is released into the air, mixed with steam and falls to the ground as acid rain. In any case, scientists say that we will not give up the "black stone" because it is both cheap and affordable. Therefore, there is no other way but to reduce its damage to the environment and ecology.

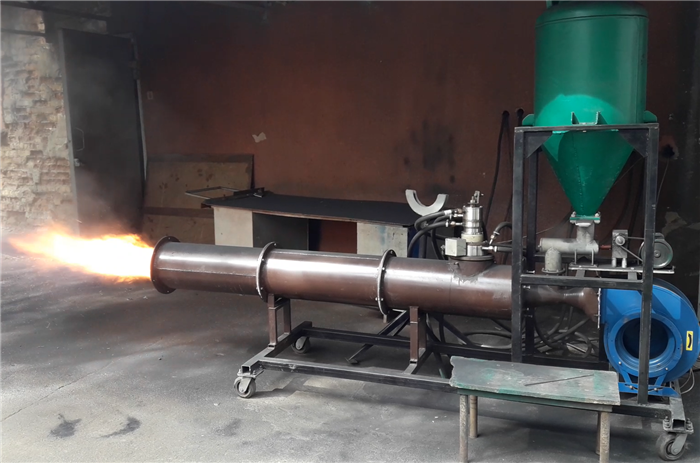

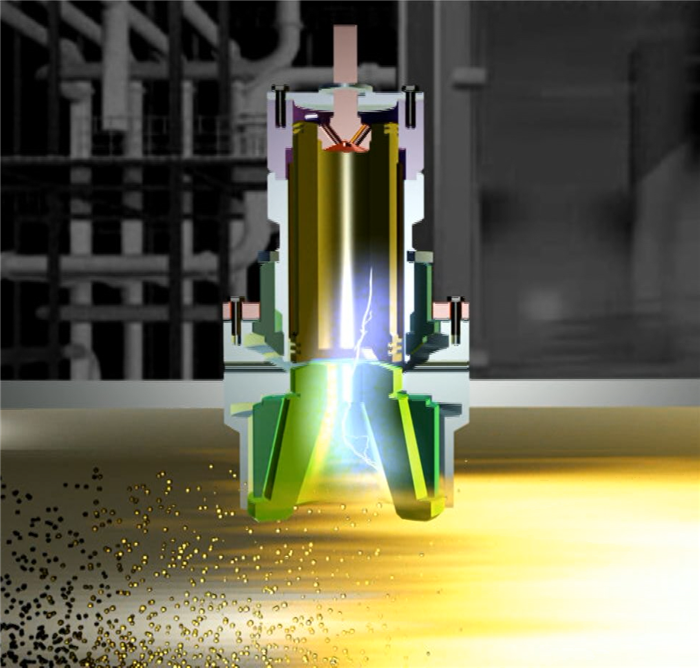

Because production depends on coal capacity. But there is a problem here: our mines are dominated by low-grade and high-ash coal dust. In fact, the exhaust gas contains a lot of harmful impurities and ash. How to reduce its size? Is there a way to get rid of black dust and ash? This is the key problem that domestic scientists have found. They developed a plasmatron to equip the dust-coal boilers of thermal power plants with plasma filling systems and increase energy efficiency, which ensures the combustion of the boiler without the use of fuel oil. It was once exhibited at the international exhibition EXPO-2017.

What project is this? What is its economic efficiency? We asked these questions to the author of the project, Doctor of Technical Sciences, Professor of the Department of Thermal Physics and Technical Physics of Al-Farabi Kazakh National University Vladimir Messerle.

It is easier to pay a fine than to install a plasmatron

The "foundation" of this project was laid in the 90s of the last century. Since then it has matured.

- If we install a plasma-fuel system (PPS) in the dust boilers of all 240 thermal power plants in the country, its economic efficiency would be 50 billion tenge per year. We do not add to this the environmental efficiency of harmful wastes and incompletely burned fuels, which will be reduced with the introduction of POZ. This means that the project, along with a positive economic performance, has great environmental impact, - said Vladimir Messerle.

Given the fact that almost all of the total thermal coal produced in the country is of low quality, the relevance of the project is self-evident. As a result, 10-15% of coal in thermal power plants does not burn. Where does unburned coal go? Of course, it does not disappear by itself. It emits smoke from the chimney and pollutes the air. Unburned carbon and flue gas containing nitrogen and sulfur oxides mix with water vapor in the atmosphere and fall to the ground in the form of acid rain. This can be solved by heating the air to 5-6 thousand degrees by means of a plasma-fuel system (plasmatron) and even by burning a plasma flame with a lot of ash from the cold kiln. As a result, it burns completely. When using the plasmatron, there will be no visible black smoke and dust at any power plant. The amount of harmful emissions into the air: nitrogen oxides - 50, and sulfur oxides - 30-40 percent.

It is worth noting another advantage of plasma technology. For example, in the case of faster burning of coal and more complete combustion, the height of the boiler can be reduced by 25-30%, which reduces the metal capacity of power equipment. Despite such economic efficiency of the software, the implementation of the project is difficult. And it is widely used abroad.

- The presentation of the project usually goes well, but when the issue reaches the feasibility study, investors are disappointed. Entrepreneurs do not like the fact that the project will pay off in four years. It is much easier for them to pay environmental fines than to modernize boilers, - says the author of the project.

Our technology is used in China

If we take into account that the energy sector is the basis of production, the issue is very relevant. Isn't it known that the rest of the basic production center will develop with this energy source?

The situation with existing thermal power plants in the former Soviet Union is about the same. Their resources are depreciated, 60-70% are at the level of depreciation. New power units will not be introduced. In this regard, the scientist expressed his opinion: "We are still working with the equipment of the former USSR. As a result, we cause great damage to the environment or spend a lot of money on the elimination of hazardous waste. If we did not allow the formation of waste at the initial stage, we would not have suffered such losses and mistakes. "

Modernization, technological re-equipment of the high ecological and economic indicators mentioned in the Address of the President of the country is a modern requirement. These days, the introduction of old equipment into production is expensive and environmentally inefficient. In this regard, the President instructed the government to work with businessmen to develop a comprehensive program of technological re-equipment of basic production. It is impossible to talk about technological progress without such work. The invention of domestic scientists, this plasma-fuel system was introduced into production in China. The author of the idea said: “Our technology is used in China. They revived the idea and equipped 627 boilers in their country with our system. As a result, it has achieved economic efficiency of 25 billion yuan since 2008. For comparison: there are 240 dust-coal boilers in Kazakhstan. China solved this problem quickly with the support of the state: the government made a decision in 1995 after I conducted the first test of anti-aircraft missiles in that country. At that time, they set up a special state-owned company and allocated funds. Thus, in 2002, in addition to his country, he entered the markets of Russia, Turkey, Korea and Indonesia. Today, five state-owned companies are involved in the introduction of plasma technology in the energy sector in China. "Each of them earns billions of yuan a year and improves the environment."

According to Vladimir Messerle, when he presented his project in China, the Chinese media reported that the innovation of our scientist was "an invention of Chinese scientists with the participation of Kazakhstan." After that, the scientist refused to sign a contract with Siemens, which gives us the right to use our domestic technology around the world.

Public project

In 2022, JSC "Samruk-Energy" intends to launch a system of fuel-free combustion of boilers.

Over the past decade, the world has paid special attention to improving the efficiency and environmental safety of solid fuel combustion in dust-fired thermal power plants (40.6% of electricity and 24% of thermal power).

JSC "Samruk-Energy", which is responsible for increasing capacity in the country, uses fuel oil to ignite and burn boiler units in the production cycle. For example, Ekibastuz GRES-1 LLP consumes 6,600 tons of fuel oil per year for this purpose, which is equivalent to 1 billion dollars. Modernization of oil refineries contributes to the reduction of production of this type of fuel. For example, the decline from 3.05 million tons in 2017 to 2.06 million tons in 2018. Despite the decline in production, fuel oil prices are rising. In 2017, its tonnage was 52 thousand tenge, in 2020 it increased to 130 thousand tenge.

Plasma-fuel system is used as an alternative technology for burning boiler units without fuel oil. At one time, this project was in the form of EXPO-2017. Today, this technology is used in many countries around the world.

Serik Totebayev, Director of Production and Asset Management of Samruk-Energy JSC, has several scientific papers on the introduction of plasma-fuel systems in thermal power plants. By the way, S. Totebayev is a student of Vladimir Messerle. He told the media: “It was not put up for industrial sale because there was no need for prototypes of equipment developed by scientists at the Kazakhstan Institute of Combustion Problems. Decades later, it began to be considered a necessity. After the decline in fuel oil production, the increase in the price of liquid fuel was recognized as an economically justified and effective step.

In 2019, employees of GRES-1 LLP, with the support of CITIC Construction Co LTD, made a special visit to power plants and equipment plants operating in China with plasma-fuel systems. They got acquainted with the equipment of several companies. As a result, it became clear that there are economic benefits due to the difference in the cost of fuel oil and coal. In particular, the plasma technology of ignition of thermal coal allows to establish at the initial stage of the block combustion process. When the unit is ignited with fuel oil, the equipment has to be switched off and on with all fuel oil injectors.

Thus, in 2022, JSC "Samruk-Energy" intends to launch a system of fuel-free combustion of boilers. Vladimir Messerle, a scientist who heard such good news, said: “Eventually, our project received high attention. If the equipment is introduced in domestic thermal power plants, our work will not be wasted, ”he said.

Fact and Accuracy

In January-September 2020, the country produced 78 million tons of coal. This is similar to the corresponding period of 2019. The volume of imports amounted to 483.7 thousand tons. This is 7.6% higher than in 2019.

Gulzat NURMOLDAKYZY